Identifying the ideal component cleaning system for a cleaning requirement can be time-consuming and a significant financial investment for any precision engineering company. Cleaning technology is continually advancing and while engineers focus on the physical systems and their capabilities in terms of technical specification, build quality and capacity, very often less consideration is given to another critical part of the process – the wash chemicals to be used, according to John Pattison, Managing Director of MecWash Systems Ltd.

“Cleaning components to the standards expected by the world’s major OEMs is a significant challenge. Companies manufacturing precision machined components are under continuous scrutiny from their customers over the quality of their products. It can often be the make or break element in maintaining a contract or winning new work,” said John.

“A company considering a washing system for a critical application will normally focus on the cleaning standard achieved by the system, perhaps measured by using a Millipore test or looking at surface energy after washing. When trying to enhance the results, customers concentrate on the physical characteristics of the wash system, e.g. pump pressures or ultrasonic power.

“The wash chemical selected is often a secondary consideration. However, in many applications understanding the chemistry and how the chemistry interacts with the component substrate, the contamination and the wash system characteristics is the key to a cost-effective cleaning solution”

Many engineers consider the chemistry a "dark art", as they are not so familiar with the options and their implications. However, the chemical analysis must be a rigorous scientific process if the best results are to be achieved.

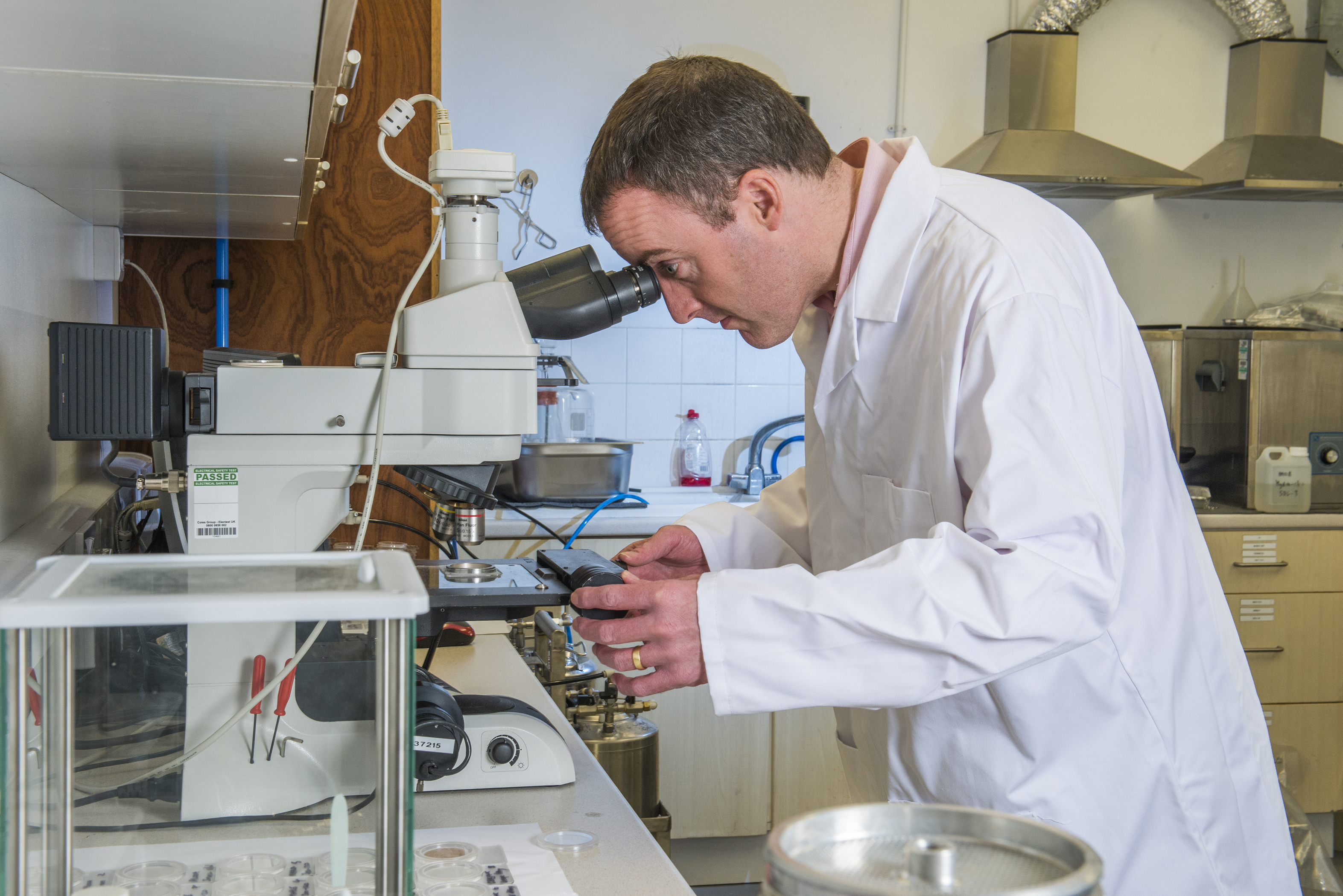

That is why MecWash, the UK's leading precision aqueous parts cleaning and degreasing systems manufacturer, have an in-house laboratory for the analysis, design and production of chemicals for specific washing applications - pictured below.

Based at its headquarters in Tewkesbury, Gloucestershire, MecWash has a team of specialists who work on the chemistry of cleaning.

“We work closely with our customers to identify their needs and understand the components being cleaned to achieve their cleanliness specifications. This includes investigating the component substrate, contamination and the preferred cycle time.

“We have our own range of wash chemicals or we can use the customer’s preferred suppliers. However, if that fails to give the results the customer needs, then we can design a bespoke wash chemical that works with our washing system to produce the cleanliness results required. It is only when the process and chemistry is fully understood that we specify a machine that is suitable.”

And it doesn’t end there. In-house laboratory cleanliness testing and analysis are undertaken to ensure the perfect results are being achieved before final commissioning and ongoing customer support continues afterwards.

“A customer will sometimes want to change the use of a machine, introduce a new component of differing geometry, substrate or cutting oil/coolant. This means the chemical balance will change in the wash and rinse process.

“We would then advise on the changes in chemistry and process required to ensure a good result is achieved. In some cases, we might be dealing with a more unusual application, and analysis within our laboratory will ensure a correct wash chemical is selected”, said John Pattison.

"A prime example is Hellerman Tyton who came to MecWash with a very tough cleaning challenge. Plastic components with sticky contamination, yet the parts were vulnerable to damage at normal washing temperatures. We devised a detergent that was particularly effective on their contamination at low temperatures."

Hellerman Tyton, the cable management solutions specialist, now achieves high quality component cleaning, within strict temperature constraints. The facility, comprising a MecWash Midi wash system with an integrated Aqua-Save waste water recycling system, is central to production at the Devon-based company and, critically, it has been configured to avoid the risk of product shrinkage. An image of MecWash Systems at Hellerman Tyton can be seen below.

Lina Ficken, Engineer Team Leader, explains: “It is important that, following the expansion process, mouldings are comprehensively cleaned before further handling and assembly processes, not least to remove a silicone coating used during the manufacturing process.

“Our customers apply the cable protection systems on site via the application of heat which shrinks them into position – temperature is clearly a factor that needs to be tightly controlled during manufacturing,” she adds. “MecWash have been able to configure the cleaning system so that wash temperatures are held at no more than 40°C, which in conjunction with the tailored AC33 chemical solution that the company was able to develop for us, ensures that all material leaves the cleaning process in the optimum condition.”

“MecWash worked closely with the Hellerman Tyton team for many months, developing the AC33 chemical, which is formulated to clean the plastic components effectively at low temperatures,” explains John Pattison, Managing Director at MecWash Systems. “MecWash’s expertise in wash chemistry is based on years of designing tailored chemicals for the most testing wash challenges for individual customers, as well as manufacturing our own range of general wash chemicals and inhibitors.”

Another long-standing MecWash customer, Advanex Ltd, based in Nottinghamshire, came to us with a chemistry conundrum. Advanex Ltd is part of a global group with more than 20 operations worldwide, covering the military and aerospace, automotive and medical industries. An image of MecWash Systems at Advanex can be seen below.

Their specialist products must be completely free from all contaminants before they can be used – consistent cleanliness to a high standard is essential. To add to the challenge, the product range includes extremely delicate components that post production cleaning processes must not distort or damage.

The challenge presented to MecWash was that there was no one process to de-scale, clean and brighten the components in one go whilst still offering “during and post process” protection. MecWash combined its chemical and process expertise to provide a solution to all these issues. The purpose formulated aqueous cleaner developed for this application cleans and protects all of the sensitive components and offers a permanent bright finish. Dull or discoloured components were de-scaled and brightened.

Following extensive trials at MecWash’s dedicated lab at its Tewkesbury headquarters, the aqueous cleaner combined with the MecWash AVD 300 aqueous cleaning system proved it was more than capable of meeting Advanex’s stringent cleanliness requirements.

Mr Rob Newham from Advanex Europe Ltd, comments, “We trialled several companies to achieve improved cleanliness for our parts; MecWash was not only able to supply the most suitable equipment, it also provided the correct chemical formulated to our requirements, achieving fantastic results that were beyond our expectations.”

MecWash employs a PhD chemist to develop bespoke formulations of wash fluid to best meet the requirements of each individual customer. Managing Director, John Pattison, explains, “MecWash understands that all of our customers have their own specific requirements and objectives – we work closely with them throughout all stages of the project to ensure we achieve the best results possible, rather than offering a ‘one size fits all’ approach.

“This attitude has resulted in us building a number of long-term relationships with customers who trust us with all of their component cleaning requirements because we take the time to really understand their needs.”

One of MecWash Systems’ existing customers came to them with another challenge. This customer provides surface engineering and component maintenance for steel rolling and processing equipment.

Prior to maintenance and refurbishment, steel rolling bearings need to be clean and dry with all traces of lubrication grease removed. The particular lubrication grease used for this purpose is designed to provide continuous and consistent lubrication to heavy engineering components under extremely challenging conditions. The grease is designed “not to come off”, which meant its removal was a time-consuming and labour-intensive manual operation using a non-environmentally friendly vapour degreaser. The company wanted to move away from using solvents.

MecWash was invited to investigate and come up with a practical solution. Thanks to MecWash Systems’ expertise and chemistry experience, it was established that the tenacious grease required substantial thermal, mechanical and chemical energy to break it down and remove it from the bearing surface.

John Pattison says: “After testing off the shelf aqueous detergents, our chemist returned to the chemical drawing board and formulated a purpose-engineered chemical to break down and remove the grease, and convert it into both a liquid and a solid form. The chemical solution AC43 combined robust detergency and with sophisticated de-emulsifying technology to remove the denatured grease and its by-products as well as simultaneously control the foam generation via a water-soluble, non surface active antifoam package.”

Following extensive trials at MecWash’s lab, the combination of the Duo 600 component cleaning system and AC43 proved it was more than capable of meeting the customer’s stringent cleanliness requirements.

The customer explained that after trialling several companies to achieve improved cleanliness for their part, MecWash was not only able to supply the most suitable equipment, they also provided the correct chemical formulated for their requirements, achieving fantastic results that were beyond the customer’s expectations. The change-over from the labour intensive manual system has enabled the customer to not only improve production, cleanliness and output, but it has also reduced manual handling, process time and waste.