In today's rapidly advancing technological landscape, the allure of the newest machinery is undeniable. However, as concerns about environmental sustainability and cost-effectiveness grow, more businesses are turning to refurbished options as a viable alternative. This article will take you inside the refurbishment process and reveals how MecWash breathes new life into its machines.

MecWash provides the ultimate flexible aqueous component cleaning and degreasing systems. These systems are designed to process complex and intricate machined or pressed parts that require very high standards of cleanliness and dryness, and the removal of all types of contamination from soluble and mineral oils to greases, polishing compounds, lapping pastes and dye penetrants.

What does Refurbished mean at MecWash?

Refurbished parts washing machines are pre-owned products restored to full working condition after undergoing rigorous testing and repairs as needed. Unlike used items sold as-is, our refurbished machines come with a warranty, providing a sense of security.

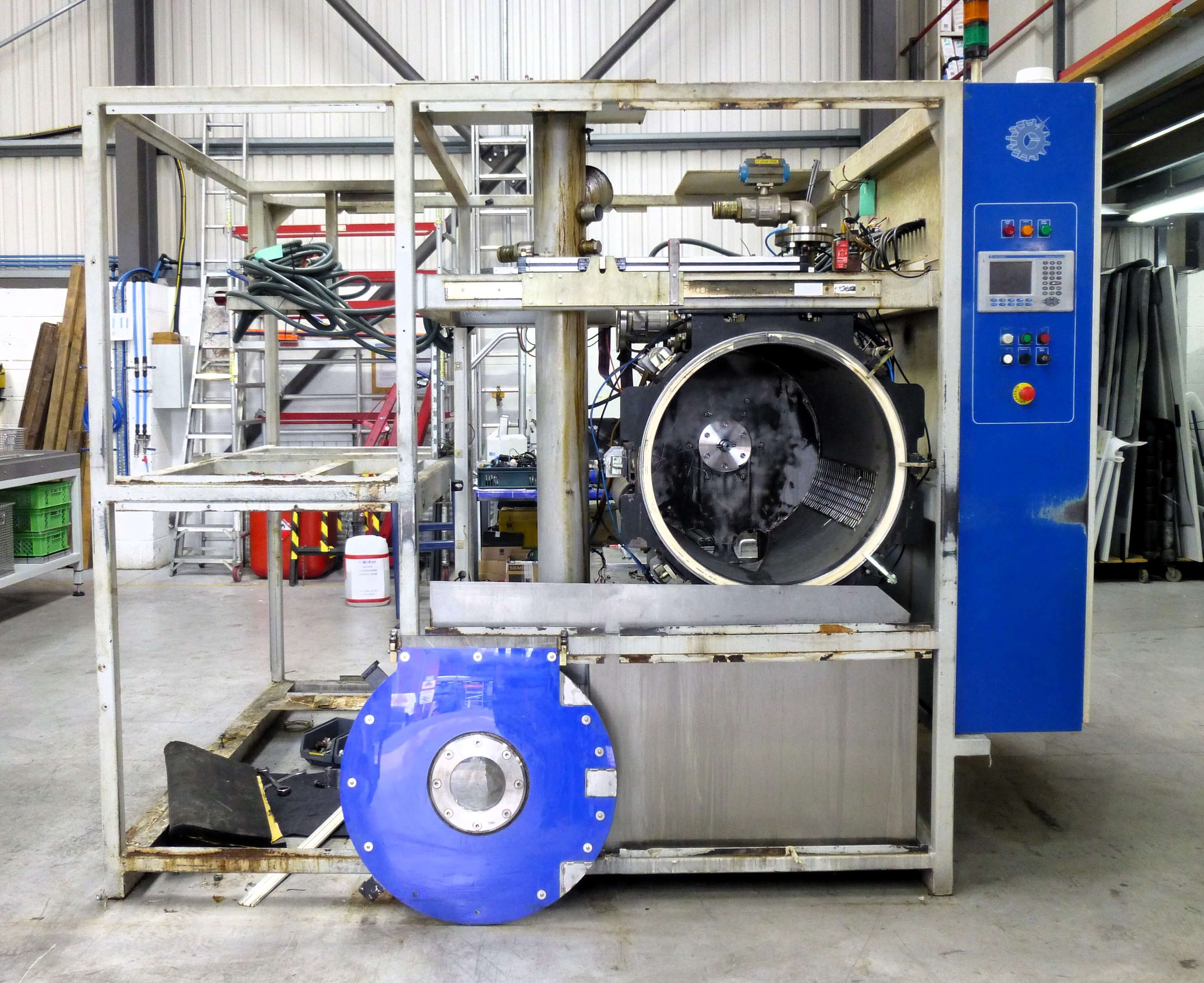

Our refurbished machines come from various sources, including trade-ins from customers upgrading to new systems. Once collected, each machine undergoes an initial diagnostic assessment, which is crucial in determining the work programme required.

The Process

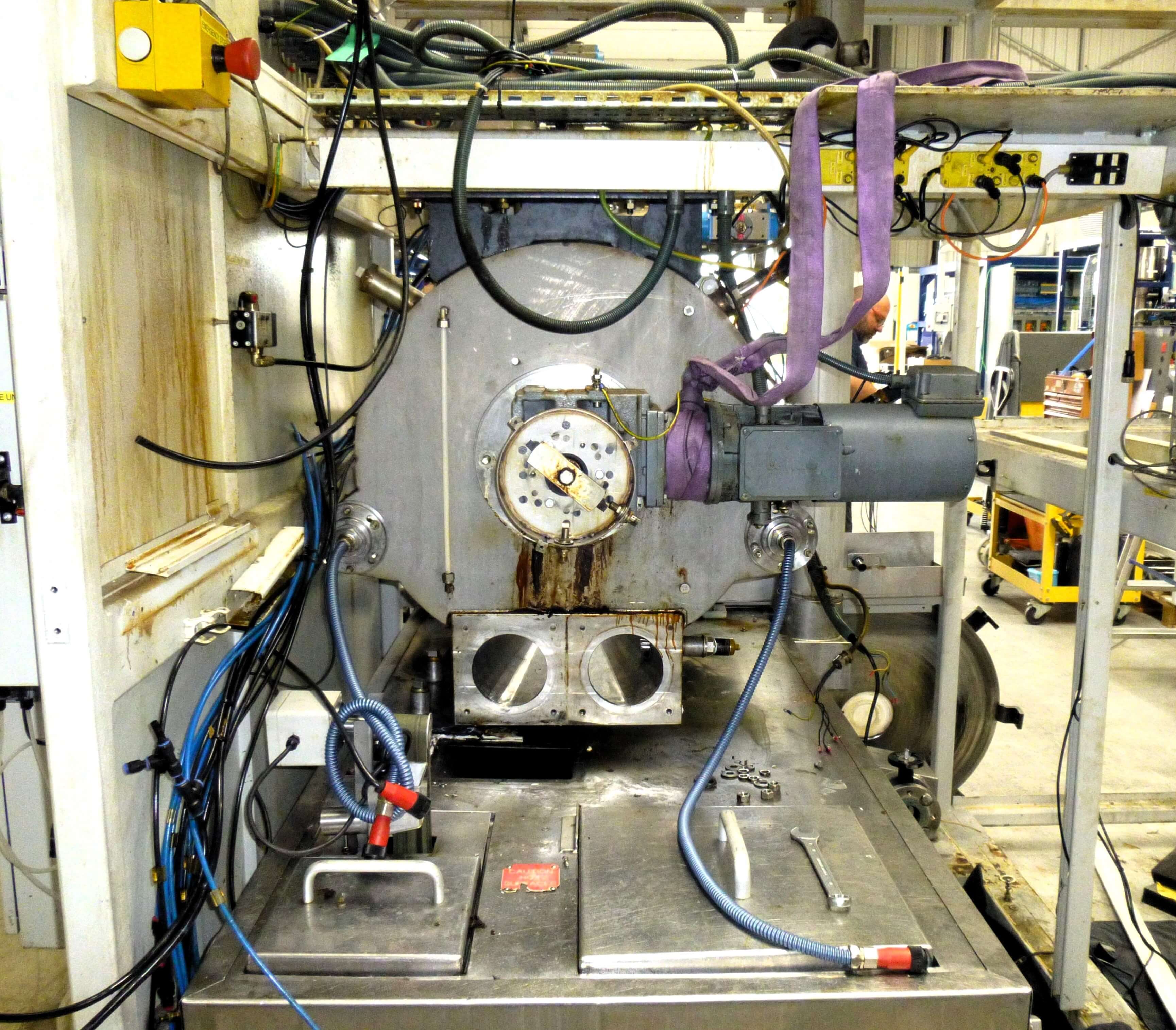

These machines are then disassembled by technicians, whilst inspecting the components for signs of wear, damage or failure. This examination helps create a precise roadmap for the refurbishment, ensuring that no stone is left unturned in restoring the machine’s functionality and aesthetics.

After disassembly and inspection, the machine and its components undergo a rigorous cleaning process. Oil, swarf and other contaminants are removed to ensure a clean slate for the refurbishment. Where necessary, the frame and panels may be completely repainted to prevent corrosion and provide a good finish.

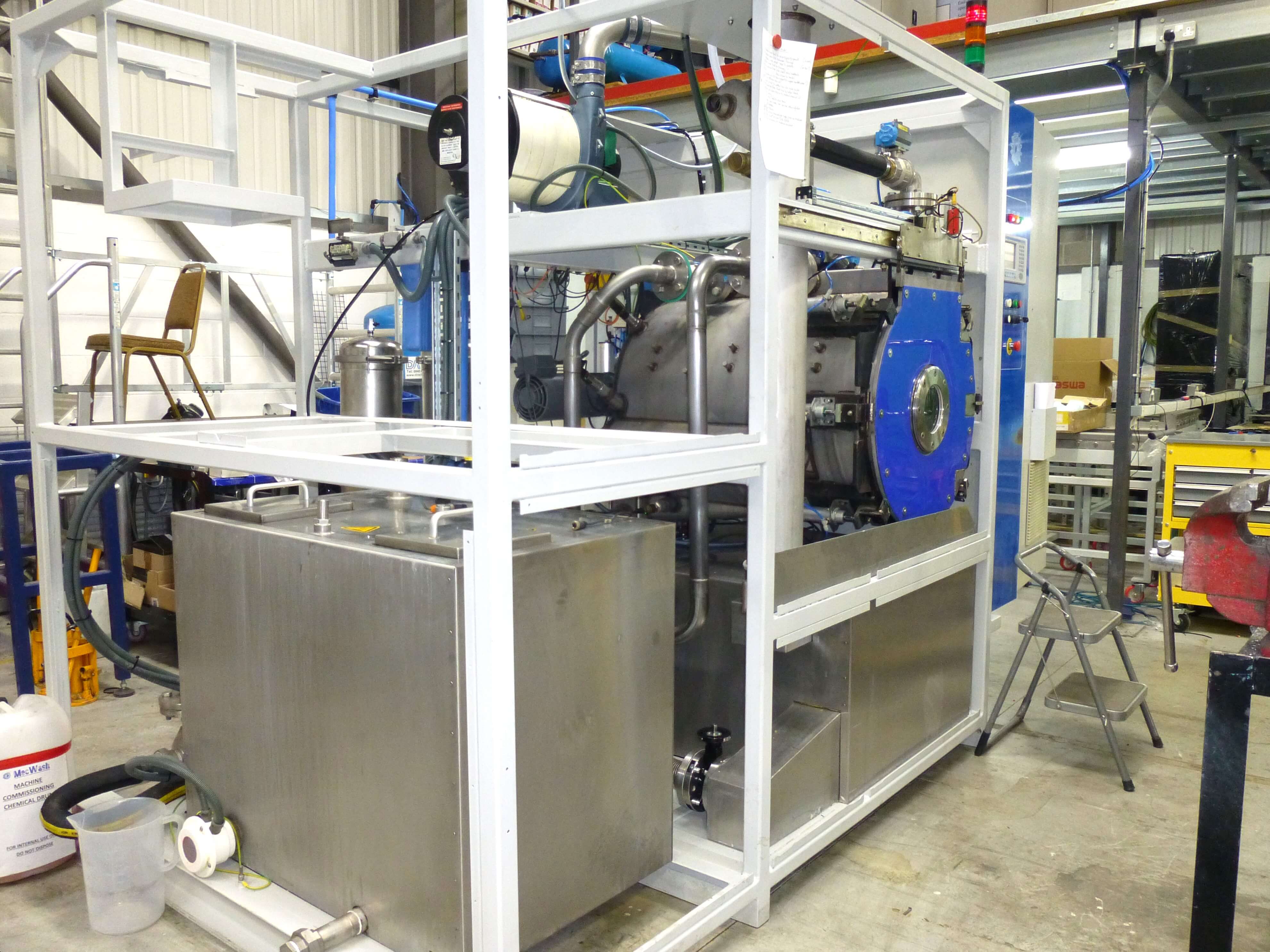

Once all the components are cleaned and necessary parts replaced, the machine is carefully reassembled. Technicians adhere to strict guidelines to ensure that the reassembly process maintains the integrity and functionality of the original machine. Where necessary, the machine is upgraded with the latest software or firmware updates, so the old equipment can communicate with any new replacement components.

After being reassembled, the machine is tested, both for performance and quality checks. Testing is possibly the most critical step in ensuring the successful refurbishment and guarantees that our machine is ready for its next life.

Environmental Impact & Cost-Effectiveness

One of the most compelling reasons to consider refurbished machines is their positive impact on the environment. By giving a second life to these machines, we significantly reduce waste and conserve valuable resources and energy.

Beyond environmental benefits, our refurbished machines present an attractive option for budget-conscious businesses, as they are considerably cheaper than a new system. A 10- or 20-year-old machine may not have the high specification of our latest top of the range systems and they may not integrate so easily with factory control systems. However, for many applications they provide all the washing performance required, coupled with the renowned quality, reliability and support that MecWash Systems are known for.

Why do people buy refurbished machines from MecWash?

- MecWash quality and reliability at an easily accessible price point

- Buying direct from the OEM means the refurbishment has been done properly, by people who really understand the machines

- A Warranty which demonstrates our confidence in our refurbished machines and provides you with protection should an issue arise.

- Support – whether you buy a new or refurbished machine, MecWash provides full analytical support for your washing applications with our in-depth knowledge of cleaning processes and chemistries.

Our refurbished machines offer a compelling alternative to new systems for many applications, offering cost-effectiveness with environmental responsibility. As we move towards a more sustainable future, considering refurbished machinery reflects a conscious decision to support a circular economy and reduce our ecological footprint.

You can check which refurbished parts washers are for sale today.